About Us

The Wideblue team has worked together for almost twenty years designing a broad range of technology-based products for medical, consumer, and industrial applications. The team typically works on technologically challenging projects and is actively involved in products that exploit emerging technologies and cutting-edge research. We always strive to find the most effective solution for our clients, with strong leadership and a methodical approach we can successfully deliver highly engineered, desirable and unique products.

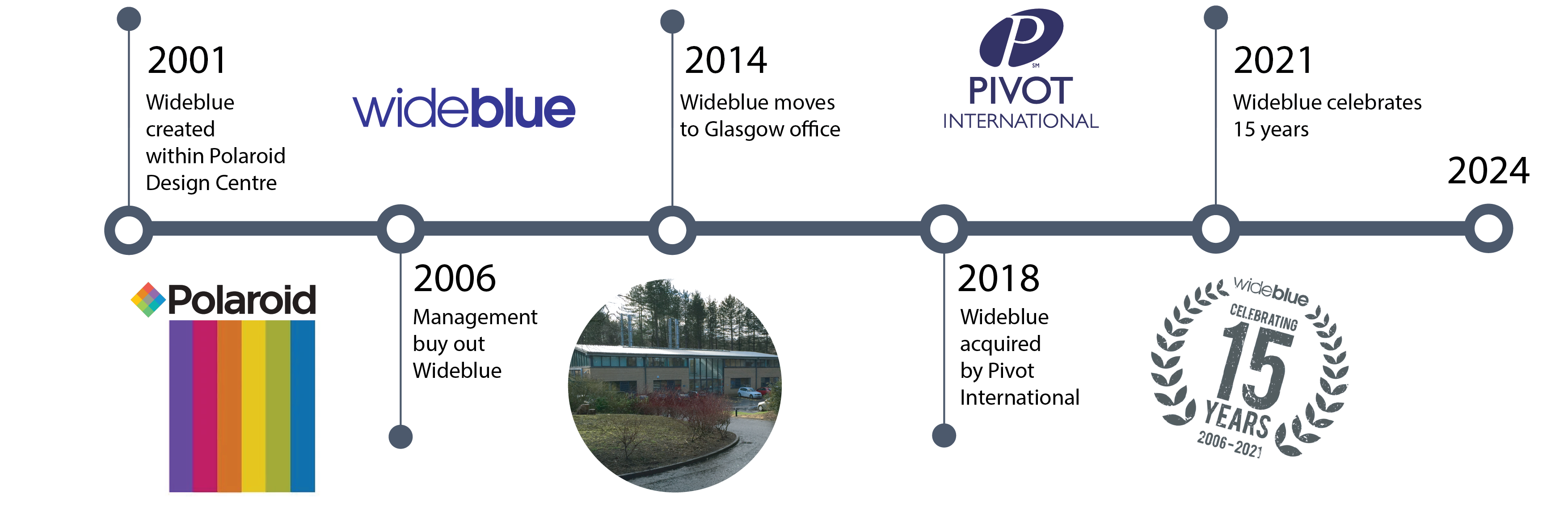

Our History

In the mid-’90s Polaroid Corporation created a European Design Centre at their Scottish location just outside Glasgow. Over the next ten years, the European Design Centre grew to the point where it employed just over 50 designers, engineers, physicists, and manufacturing development specialists and delivered all of Polaroid’s technical and commercial products.

In 2001 Wideblue was created as a division within the Design Centre and started to develop products for external clients. Five years later, Wideblue was part of a management buy-out and since then has been an independent company delivering hundreds of projects for a variety of clients ranging from lone inventors, start-up companies, and University spinouts through to multinational organisations. The unique skills that were developed designing and creating technology-based products for Polaroid Corporation are now employed in creating award-winning products for our clients.

Start-up companies value Wideblue’s first-hand experience of the technical, commercial, and funding requirements for emerging technology businesses. We act as a “virtual” product design and development team, allowing companies to develop products without the fixed costs of an in-house engineering group.

Established companies use Wideblue to complement in-house resources. For example, we work with life-science departments to design products that can commercialise their discoveries. We also apply our specialist photonics expertise to fill skills gaps in established engineering teams.

In 2018, Wideblue was acquired by Pivot International, a US-based global product development, design, engineering and manufacturing firm. Pivot owns its own manufacturing and component sourcing facilities throughout North America and the Far East. This provides our clients with a complete end-to-end solution going from the initial product idea to full-scale production.

Our Facilities

- 3D printer and Prototype workshop

- Large development lab with a broad range of test and measurement equipment

- An optical lab where we can test complex illumination and imaging systems

- Electronics assembly and test stations where we can build and debug prototype and production assemblies

- A number of software development environments for a range of microprocessors and DSPs and PC applications

- A manufacturing start-up area for low-volume manufacturing of client products including medical devices

- Software for 3D CAD, FEA analysis, photo-realistic rendering for concept visualisation, PCB design, and optical simulation

Our Customer Feedback

"Wideblue’s deep expertise in optoelectronics, working under ISO 13485 quality system, and the link to Pivot’s supply chain manufacturing have been pivotal in bringing our revolutionary N-Tidal and AI diagnostic technology system to the market.”

— Dr. Julian Carter, Director of Engineering at TidalSense

“I was impressed with the performance and reliability of the prototype in demanding trial conditions, especially as the two halves of the team were never able to meet up in person during the entire development and build process.”

— Dr. Michael Harris, ZX Lidar

“Wideblue demonstrates strong technical skills, incl. mechanics, electronics & optics, an open communication style, a large flexibility, a low overhead and a can-do mentality.”

— Tom Claes, Antelope DV

“Reviews, held weekly, ensured good communication and clarity about options and progress. The quality and presentation of these by Wideblue was very good.”

— Tim Lukins, Machines with Vision

“The contribution made to the LUSS project was outstanding. The work was completed on time, to budget and to an exceptionally high standard.”