Bohem Blade Optical Health Monitoring

Product Brief:

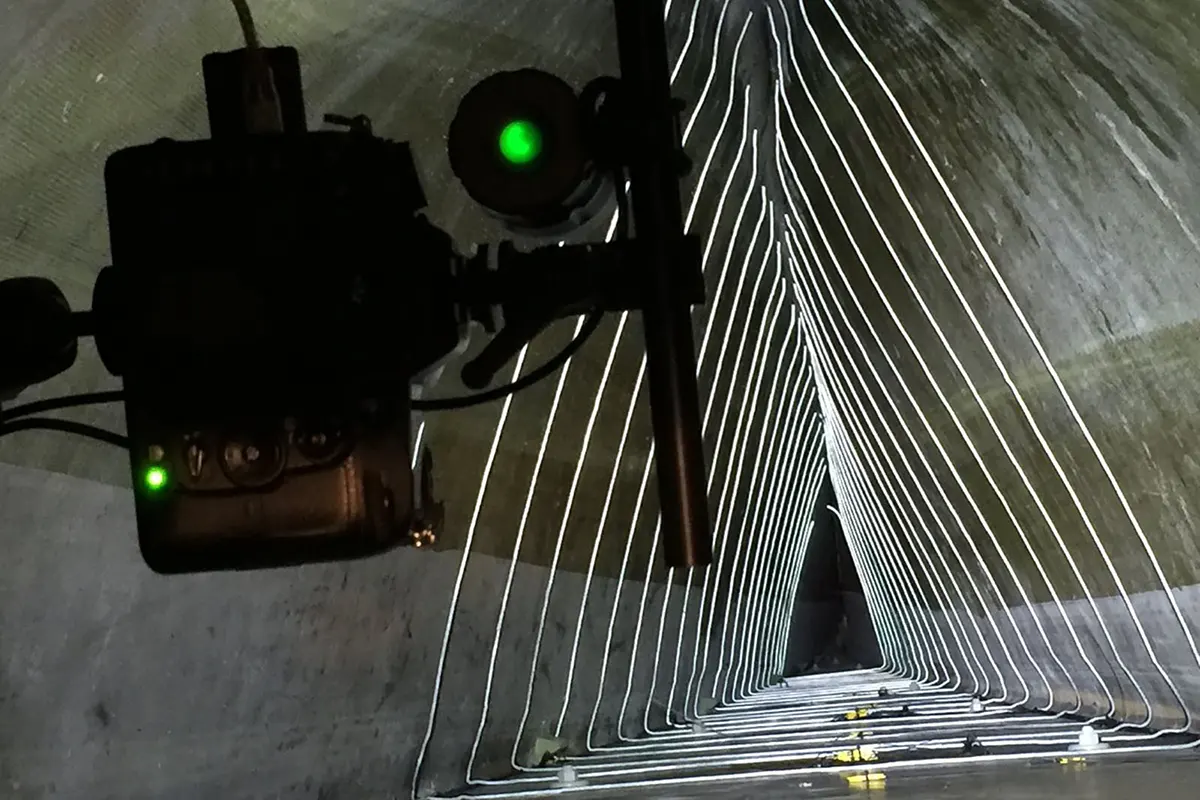

Working in collaboration with the Offshore Renewable Energy (ORE) Catapult, Wideblue developed a root-mounted IP-rated vision system that meticulously tracks the displacement of a series of reflective markers installed on the inner surface of a wind turbine blade. These reflective markers are passive, low-cost, and easy to install and can be removed without damaging the blade, ensuring the system’s precision and reliability.

Our Approach:

The vision system images the movement of the markers in real time while the blade is in operation. The resulting data is used to plot the cross-section movements, deflections, and panel “breathing” of the blade.

The ORE team tested BOHEM against point laser measurements in 5m and 20m blades and found that accuracy is within 0.1mm to 1mm of the laser measurements. BOHEM also provided an excellent correlation with FE Analysis of blade design.

Once installed, the system can be used in many different ways:

- Blade developers can monitor real deflection at various parts of the blade using the information to make blade design and strengthening decisions.

- Blade/turbine manufacturers and testers can use the data to predict blade life.

- Turbine operators can use BOHEM data to inform inspection and maintenance schedules and track blade health in all wind conditions over product life.

Our Solution:

Wideblue undertook all mechanical, optical, electronics, and software design, ensuring a fully engineered prototype for benchmark testing. This comprehensive approach underscores our commitment to delivering a high-quality, reliable product.